Case Study: How Nimbl Streamlined Operations and Cut Procurement Time by 83% with Response

Introduction Name: Nimbl Fulfillment

Industry: Fulfillment & Logistics

Headquarters: Salt Lake City, Utah

Key Stakeholder: Sterling Westfall, Head of Operations "Response has transformed our procurement process. The time savings alone make it worthwhile, but the real value lies in the visibility and control we now have over our spend. Our managers are more efficient, our accounting team is happier, and we're running a leaner operation overall."

— Sterling Westfall, Head of Operations, Nimbl Fulfillment

Nimbl Fulfillment, a fast-growing fulfillment and logistics provider, faced challenges typical of many mid-sized logistics companies. With a wide array of vendors, decentralized procurement, and manual processes, inefficiencies were holding them back. Enter Response, a centralized procurement platform that streamlined indirect spend management and brought visibility, control, and automation to Nimbl's operations. Results "Before implementing Response, it took about two full days (16 hours) per month for accounting to reconcile and categorize everything manually. Now, with Response, it takes only 30 minutes to an hour."

— Sterling Westfall, Head of Operations, Nimbl Fulfillment

Nimbl Fulfillment experienced measurable improvements in efficiency, cost management, and team morale after implementing Response:

Significant Time Savings

Procurement became dramatically more efficient, with managers reducing time spent on orders from 1 hour to just 10 minutes per session, saving 50 minutes every other week per manager. On the accounting side, reconciliation time dropped from 16 hours a month to under 1 hour, freeing up valuable labor hours for higher-priority tasks.

Enhanced Budget Control

Real-time visibility into departmental budgets allowed managers to proactively manage their spend. As a result, rogue spending decreased from 50% to less than 1%, with nearly all procurement now centralized and tracked through Response.

Improved Operational Efficiency

The streamlined procurement process eliminated the need for managers to over-order supplies, leading to a 30-50% reduction in inventory overstocking. This shift not only reduced waste but also freed up cash flow by aligning orders with immediate business needs.

Boosted Team Morale

By giving teams autonomy to make procurement decisions within set guardrails, Response fostered trust and improved efficiency. Accounting staff also benefited from simplified workflows, eliminating time-consuming and tedious manual processes.

These results showcase how Response empowered Nimbl Fulfillment to save time, cut costs, and improve operations at every level. The Challenges Fragmented Vendor Management

With dozens of vendors to manage, each requiring separate logins and unique processes, procurement was both disjointed and time-consuming. The team relied on manual orders and reconciliations, adding hours of unnecessary labor to their workloads.

Limited Visibility into Spend

Budgets were tracked manually using spreadsheets, a method prone to errors and inconsistencies. Managers often operated in the dark, lacking real-time insights into departmental budgets, which led to frequent overspending and financial mismanagement.

Inefficiencies in Approval Processes

Procurement workflows were cumbersome, involving multiple manual approvals that lacked enforcement to prevent rogue purchases. Accounting teams spent the equivalent of 2 business days each month manually reconciling invoices and categorizing expenses. Additionally, bi-weekly orders took each manager over an hour to complete, significantly impacting productivity.

These inefficiencies highlighted the urgent need for a streamlined and automated solution—a gap that Response was perfectly positioned to fill. The Solution To tackle their procurement challenges, Nimbl Fulfillment implemented Response, a platform designed to centralize and streamline operations. Here’s how it addressed their pain points:

Centralized Procurement

Response provided a single platform to manage all vendor relationships and purchases, eliminating the need for multiple logins and processes.

Enhanced Budget Visibility

With real-time insights into departmental spend, managers could proactively monitor budgets, reducing the risk of overspending.

Automation

Response simplified workflows by automating approvals, order placements, and invoicing, saving significant time for both operations and accounting teams.

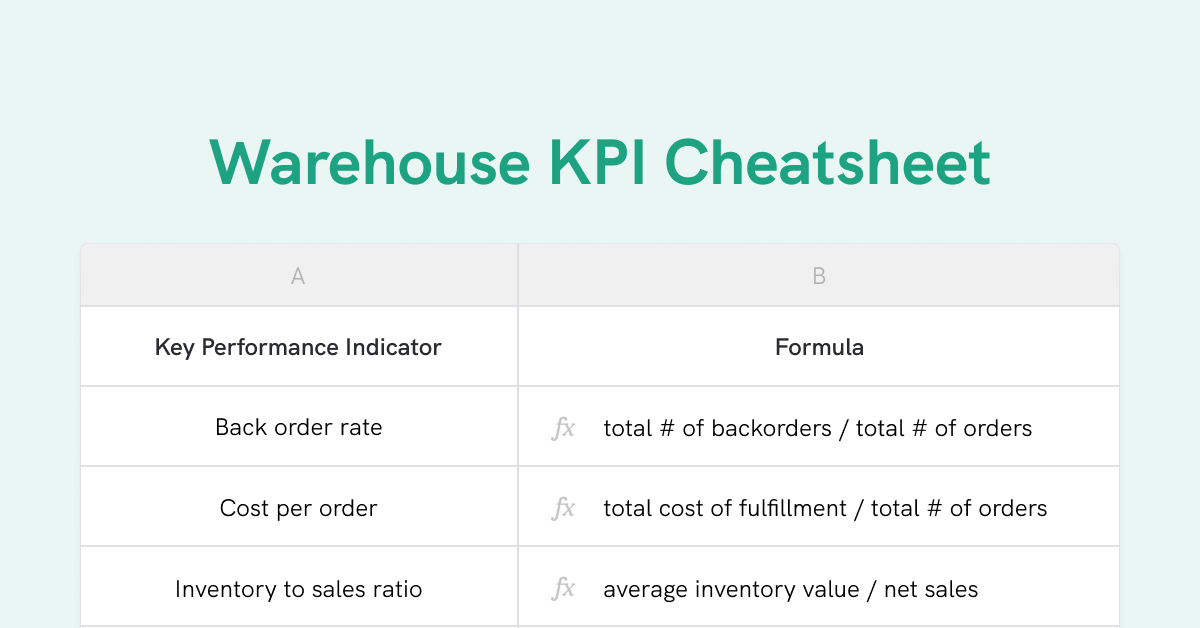

SKU-Level Insights

The platform introduced detailed tracking of purchased items, enabling better inventory management and improved spend visibility.

By consolidating these capabilities into one user-friendly platform, Response empowered Nimbl to save time, reduce inefficiencies, and take full control of their indirect spend.

Implementation and Adoption "The implementation process was fairly quick. We basically just provided all of our different vendors and within a day or so they were all set up. And then we were testing it fairly quick after that and you could immediately see the time saved from each of the different users."

— Sterling Westfall, Head of Operations, Nimbl Fulfillment Implementing Response was a smooth and efficient process for Nimbl Fulfillment:

Seamless Onboarding

With Nimbl’s vendor list in hand, Response set up all accounts in less than a day, ensuring a quick transition.

Immediate Impact

Managers experienced an 83% reduction in procurement time, cutting the process from 1 hour to under 10 minutes.

Minimal Disruption

Thanks to Response’s intuitive platform, teams were operational almost immediately after a brief training session.

This seamless adoption allowed Nimbl to see the benefits of Response right away without interrupting day-to-day operations.

Unexpected Benefits "Ordering was such a hassle before Response, managers were ordering anywhere from 30 to 50% extra just because they didn't want to order as frequently."

— Sterling Westfall, Head of Operations, Nimbl Fulfillment Although Nimbl Fulfillment adopted Response primarily for its procurement capabilities, the platform delivered unexpected advantages that extended beyond its core functionalities:

Lean Inventory Management

By reducing overstocking, Response improved cash flow and enhanced budget accuracy, helping Nimbl run a leaner, more efficient operation.

Scalability

The centralized procurement system provided a solid foundation for growth, enabling Nimbl to scale operations without a corresponding increase in overhead or complexity.

Future Insights

Nimbl plans to tap into Response’s robust data analytics for vendor consolidation and pricing negotiations, unlocking new opportunities for cost savings and procurement optimization.

These additional benefits demonstrate how Response continues to deliver value beyond expectations, empowering Nimbl to optimize operations while preparing for future growth.

Why Nimbl Recommends Response Nimbl Fulfillment found Response to be an indispensable tool for streamlining procurement and driving operational efficiency. Here’s why:

Efficiency Gains

The platform delivered immediate time savings across both operations and finance teams, dramatically reducing manual workloads and freeing up resources.

Scalability

Response’s centralized system was designed to grow alongside Nimbl, ensuring the business could scale seamlessly without additional complexity.

Control & Visibility

With real-time budget insights, Response empowered managers to make informed decisions, eliminating guesswork and enabling proactive spend management.

For Nimbl, Response was more than just a procurement solution—it became a vital tool for improving efficiency, control, and scalability across the organization.

Conclusion For Nimbl Fulfillment, Response has been a game-changer, streamlining procurement, improving budget management, and saving countless hours of labor. By centralizing their procurement operations, Nimbl is poised to scale efficiently while maintaining control over their indirect spend.

Interested in transforming your procurement process?

Book a demo today to learn more.

Case Studies